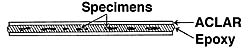

Epoxy embedments sandwiched between ACLAR® sheets

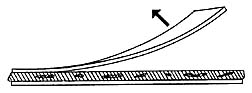

ACLAR® pulled away from the flat specimen embedment.

Cut out the area of interest and glue it on a 00 cylinder for sectioning.

Disc Punches

are available in four sizes:

5/16" (7.9mm)

3/8" (9.5mm)

7/16 (11.1mm)

1/2" (12.7mm)

For comparative TEM and SEM procedures, cut an ACLAR® circle in half and compare the

two after fixation (Kingsley3); use a blunt needle to mark.

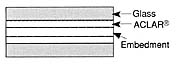

Press between glass plates

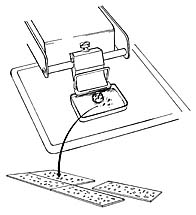

Fresh material is cut on a vibratory slicer, treated with HRP and placed on ACLAR® cut into a slide shape -

observe under LM - if OK, process for TEM on the slide.

|

|

The 1968 paper1 by E. B. Masurovsky and R.P. Bunge was the first to describe and clearly demonstrate the

useful chemical and physical properties of ACLAR® for both tissue culture and electron microscopic purposes.

It was first used in the space program and its properties were found to be interesting for biomedical research

(personal communication, Dr. E. Masurovsky). Subsequent work by others developed ACLAR® applications; attention

is brought to that done by Mawe, et al 2, and the comprehensive ACLAR® study by Kingsley and Cole3.

ACLAR® overcomes a number of problems regarding the processing of tissue culture cells, epoxy embedments,

sectioning and observations because of its chemical inertness, non-stick property, glass clarity, flexibility and

smooth surface. It may be cut with scissors or blades and does not damage microtomy knives. It is unsurpassed in

moisture barrier protection, transparent to UV and is plasticizer and stabilizer free. It is nonflammable, nonaging

and has a low dielectric constant and dissipation. It is high in dielectric strength. ACLAR® can be sterilized.

Features of ACLAR® Film:

- Separates easily from epoxy

- Transparent fluorinated-chlorinated thermoplastic which contains no volatile components

- Chemically inert, for all practical purposes, ideal for growing cell cultures

- Cells adhere to it readily and remain attached after fixation, dehydration and critical point drying or embedding

- Accepts heavy metal sputter coating

- Stable in the scanning electron microscope; melting point 202°C

- ACLAR® is as transparent as glass

- Fluorescence microscopy possible since ACLAR® exhibits no detectable autofluorescence

- Can be sectioned and does not damage ultramicrotomy knives

- Considerably simplifies the preparation of cultured cells for all types of microscopy

- sterilizable

- Gives flat sections

- Soft, can be sectioned

- Smooth surface makes light microscopy observations possible

- Does not degrade under UV or gamma ray radiation

- Used as an O2 barrier when flat embedding methacrylate or acrylic resins

ACLAR® is offered in sheet form, 8 x 12.5" (203 x 318mm) with 7.8 mil (0.2mm) thickness.

| Prod #

| Description

| Unit

| Price

| Order / Quote

|

| 10501-10

| ACLAR® Embedding Film, 7.8 mil thick, 8 x 12.5" (203 x 318mm)

| pkg/10

| $96.45

|

|

| 10501-25

| ACLAR® Embedding Film, 7.8 mil thick, 8 x 12.5" (203 x 318mm)

| pkg/25

| 182.50

|

|

| 10501-8

| ACLAR® Embedding Film, 7.8 mil thick, Roll of 12.5" W; x 80" L (32 x 203.2mm)

| each

| 79.50

|

|

References, ACLAR® Film

1. Masurovsky EB, Bunge RP: Fluoroplastic coverslips for long-term nerve tissue culture. Stain Technology, 43, 3, 161-165 (1968)

2. Mawe GM, Bresnahan JC, Beattie, MS: Ultrastructure of HRP-labelled neurons: a comparison of two sensitive techniques. Brain Research Bulletin, 10, 551 (1983)

3. Kingsley RE, Cole NL: Preparation of cultured mammalian cells for transmission and scanning electron microscopy using Aclar film. J of Electron Microscopy Technique, 10, 77-85 (1988)

ACLAR® Embedding Film

Physical & Chemical Resistance Data

Physical Data

| Density |

2.12 |

| Thickness |

7.8 mil (0.198mm) |

| Clarity |

Clear |

| Water Absorption |

nil |

Water Vapor Transmission Rate

@ 100°F (37.7°C) / 100% RH |

0.003gm / 100in² / day

(0.047gm / m² / day) |

Dimensional Stability,

10 min @ 300°F (149°C) |

<2% |

Dimensional Change,

10 min. @ 300°F (149°C) |

< 2% |

| Thermal Conductivity |

4.7 x 10-4 cal-cm/cm²sec °C |

| Crystalline Melting Point |

395.6 - 399.2°F

(202 - 204°C) |

| Flammability |

Nonflammable |

Chemical Resistance Data

| Acetone |

No effect |

| 100% Ethyl alcohol |

No effect |

| Liquid Nitrogen |

Remains flexible |

| Osmium Tetroxide |

No effect |

| Propylene Oxide |

No effect |

| Butyl Alcohol |

None |

| Carbon Tetrachloride |

Slightly flexible |

| 1,2-Dichloroethane |

None |

| Ethyl Acetate |

Very flexible |

| Ethyl Ether |

Very flexible |

| Ethylene Oxide |

Very flexible |

| Formic Acid |

None |

| Gasoline |

None |

| All Acids (HCl, H2SO4..) |

None |

| Methanol |

None |

| Toluene |

Slightly flexible |

| Plastisolve |

None |

|